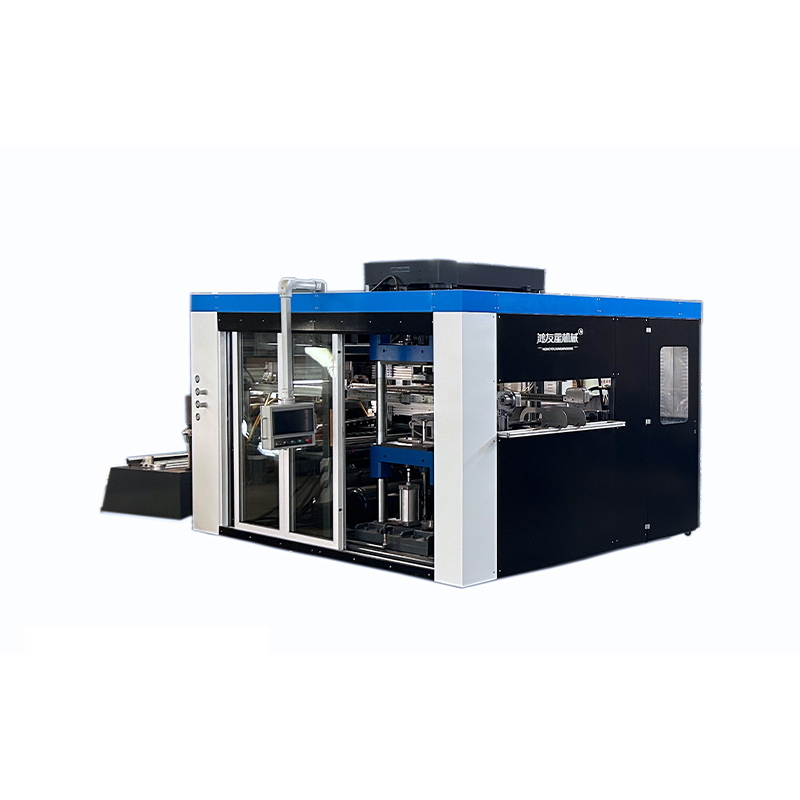

Features:

* This machine has superior functions, stable system, simple operation, convenient maintenance and wide application.

* This machine can produces plastic trays with sheets as per the date below being able to use various kinds of plastics sheet, PET, PS, PLA, recycled or virgen.

* Intelligent automation integration, eccentric crank arm linkage mechanism, the fastest work can reach 75 times per minute.

* The electric furnace adopts a three-stage upper and lower heating method, an intelligent temperature control system, and can easily correspond to thick and thin materials.

* Designed for positive and negative 150 mm molding, it can also perform positive pressure or vacuum molding independently, servo stretching device, and concave and convex molds can be produced.

* All servos for forming, punching, cutting, stacking, and feeding are all multi-turn absolute values, which ensures the stability of the system and automatic lubrification station.

* A quick mold change mechanism is designed, which is quick and easy to install and change molds, which shortens the installation cycle.

* Advanced safety protection measures ensure the safety of personnel under high-speed operation of the equipment.

Device parameters:

|

Control System

|

Inovance

|

|

Applicable sheet:

|

PETG、PET、PP、PS、PVC、

PLA、Bio-based materials and more, recycled or virgen

|

|

Drive System

|

Inovance

|

|

Molding area

|

970 x 670 mm

|

|

Pneumatic Components

|

SMC

|

|

Material width:

|

450 - 740mm

|

|

Screw slide

|

ABBA/silver

|

|

Forming height:

|

Maximum 150 mm

|

|

Main bearing

|

NHK

|

|

Forming depth:

|

Maximum 150 mm

|

|

Main industrial control

|

FUJI/LG

|

|

Stacking of pices

|

Maximum 500 mm

|

|

Heating element

|

|

|

Sheet thickness

|

Maximum 01-2mm

|

|

Pull tab motor reducer

|

Inovance 6.9 KW

|

|

Unwinder of sheet

|

Maximim width: 1060 mm

|

|

Forming motor reducer

|

Inovance 6.9kw

|

|

Roll diameter

|

Maximum 1300 mm

|

|

Stretch motor reducer

|

Inovance 2.2kw

|

|

Production speed:

|

Maximum 75 molds/min

|

|

Stacked motor reducer

|

Inovance 3.9 kw

|

|

Whole machine power consumption:

|

About 85kw/h

|

|

Mold clamping pressure

|

Maximum 90000 daN

|

|

Mechanical Dimensions:

|

L13800×W4550×H3500mm (Four-station extension 1400 mm )

|

|

Cutting pressure

|

Maximum 90000 daN

|

|

Machine weight:

|

Weighs about 8500kg

|