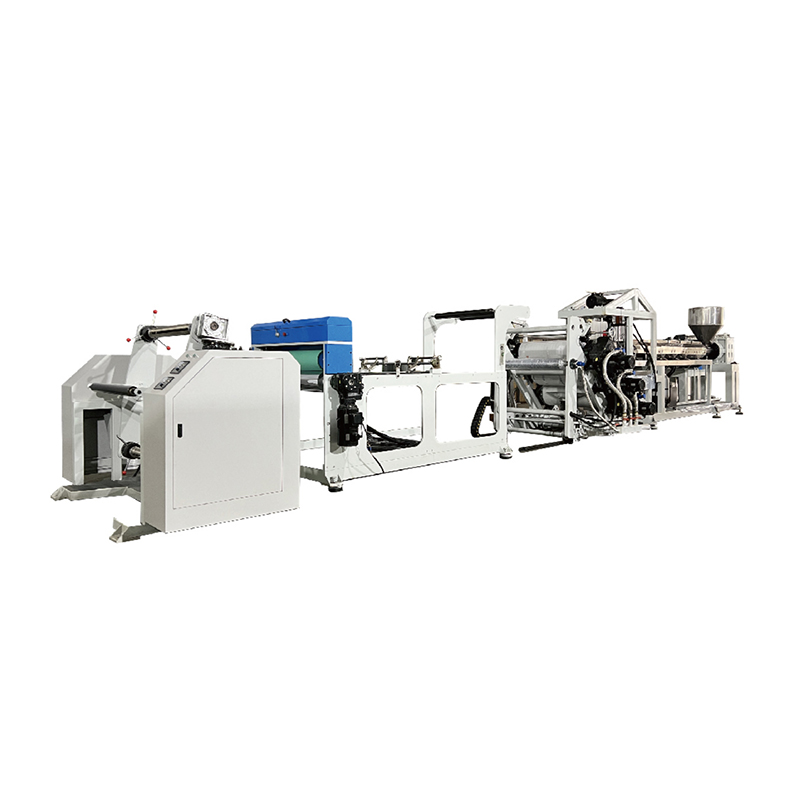

PP/PS/PE/PLA Single Screw Plastic Sheet Extruder Thermoforming Making Machine is an efficient and multi-functional plastic sheet extrusion thermoforming equipment, specially designed for processing PP (polypropylene), PS (polystyrene), PE ( Polyethylene) and PLA (polylactic acid) and other materials. It combines advanced extrusion technology and thermoforming technology to produce high-quality, high-precision plastic sheets that are widely used in packaging, construction, furniture, automobiles and other industries.

Product parameters:

Model series:

HYX-80, HYX-90, HYX-105, HYX-110, HYX-120, HYX-120 High Output, HYX-135. Different types of equipment adapt to different scales of production needs, covering everything from small and medium-sized to large-scale production lines.

Processing materials:

It is mainly suitable for the processing of PR (polyamide, also known as nylon), PS, PE and other materials, and is also compatible with the production of environmentally friendly materials such as PLA.

Material thickness:

The thickness of the sheets that can be processed ranges from 0.30 to 2.0mm, meeting the needs of different application scenarios.

Plate thickness accuracy:

The accuracy guarantee of ≤±0.015mm ensures the uniformity and high quality of the plate.

Effective width of plate:

The maximum effective width can reach ≤800mm, adapting to the production of products of different sizes.

Production line speed:

The line speed is adjustable between 3~20 m/min, and the fast and efficient production process ensures output and efficiency.

Maximum production capacity:

Depending on the model, the maximum production capacity ranges from 90kg/h to 550kg/h to meet the needs of production lines of different sizes.

Maximum roller diameter:

The maximum roller diameter can reach 800mm, ensuring the stability and processing capacity of the equipment.

Number of layers:

The equipment supports the production of single-layer boards, which is simple and efficient.

Motor Power:

The motor power ranges from 30kw to 185kw. The strong power support ensures the stable operation and efficient production of the equipment.

Features:

Efficient and stable: The equipment adopts advanced extrusion technology and thermoforming technology to ensure high efficiency and stability of production.

High precision: The plate thickness has high precision, ensuring product quality and consistency.

Wide applicability: Suitable for processing a variety of materials to meet the needs of different industries.

Flexible and adjustable: The production line speed and production capacity are adjustable to adapt to production lines of different sizes and needs.

Application scenarios:

Plastic packaging industry: produces various types of plastic packaging boxes, trays, etc.

Construction industry: Produces plastic panels for construction, such as sound insulation panels, heat insulation panels, etc.

Furniture industry: produces plastic furniture panels, such as tabletops, cabinet doors, etc.

Automotive industry: production of automotive interior parts, sound insulation parts, etc.

This PP/PS/PE/PLA single-screw plastic sheet extrusion thermoforming machine has become an indispensable production equipment in many industries due to its high efficiency, stability and high precision.

English

English عربى

عربى 简体中文

简体中文

+86 18621972598

+86 18621972598  +86 186 2197 2598

+86 186 2197 2598

No. 565, Xinchuan Road, Xinta Community, Lili Town, Wujiang District, Suzhou City, China

No. 565, Xinchuan Road, Xinta Community, Lili Town, Wujiang District, Suzhou City, China