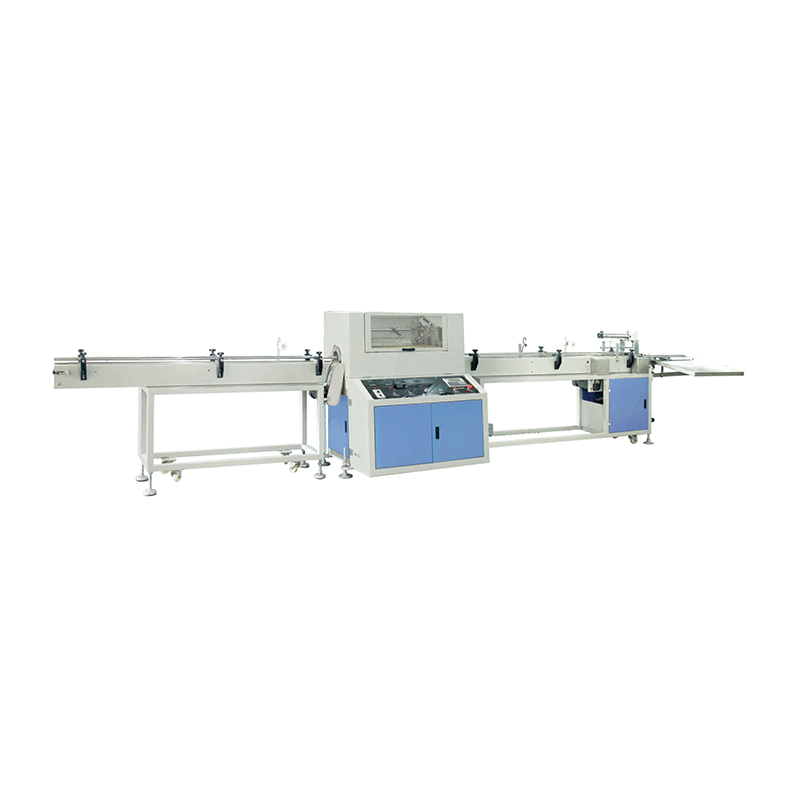

In modern beverage packaging production, plastic cup rim rolling machines with high efficiency play a crucial role in ensuring that cups are consistently shaped, durable, and aesthetically finished. These machines are designed to automate the process of curling or rolling cup rims, enhancing both production speed and product quality.

A plastic cup rim rolling machine with high efficiency is a specialized piece of equipment designed to curl the top edges of plastic cups, providing a finished, smooth rim that enhances both usability and strength. Unlike traditional manual or semi-automatic rim rollers, high-efficiency models incorporate automation and precision engineering to optimize speed and consistency.

Key characteristics of high-efficiency models include:

The versatility of a machine in handling different cup sizes and materials is particularly relevant for manufacturers producing various cup designs for drinks, desserts, or disposable containers.

One of the primary considerations for buyers is the machine’s ability to manage cups of various diameters and heights. Modern production lines often require flexibility to produce multiple cup specifications without changing equipment or incurring significant downtime.

Factors that influence a plastic cup rim rolling machine’s adaptability include:

For manufacturers, investing in a machine that handles multiple cup sizes efficiently reduces production interruptions, increases output, and enhances overall operational efficiency.

Plastic cups can be made from a variety of materials, including polypropylene (PP), polyethylene terephthalate (PET), polystyrene (PS), and biodegradable plastics. The material type directly impacts how the rim can be rolled and finished.

Plastic cup rim rolling machine with high efficiency is designed to address these material-specific challenges:

By accommodating a broad range of materials, manufacturers gain the flexibility to diversify their product lines without needing separate machinery.

The ability to handle diverse cup sizes and materials relies heavily on the technical design of the plastic cup rim rolling machine with high efficiency. Key features include:

These technical elements contribute to a machine’s ability to deliver reliable performance across different production scenarios.

While technical specifications are crucial, operational practices also impact a machine’s efficiency in handling multiple cup types. Proper setup, maintenance, and monitoring can prevent production issues.

Best practices include:

By combining advanced machine features with proper operational procedures, manufacturers can maximize the versatility and efficiency of their plastic cup rim rolling machine with high efficiency.

Having a plastic cup rim rolling machine with high efficiency that supports multiple cup sizes and materials brings several advantages:

These benefits make such machines particularly attractive to medium and large-scale beverage and packaging producers.

Despite their versatility, plastic cup rim rolling machines with high efficiency may face certain challenges:

Addressing these challenges ensures that the machine continues to deliver high-quality results across diverse production requirements.

The demand for versatile plastic cup rim rolling machines with high efficiency is rising due to evolving consumer and industrial trends:

These trends underline the importance of investing in machinery that can handle diverse production demands efficiently.

For manufacturers deciding between single-size and multi-size plastic cup rim rolling machines with high efficiency, several factors should be considered:

| Feature | Single-Size Machine | Multi-Size High-Efficiency Machine |

|---|---|---|

| Cup size adaptability | Limited | Wide range |

| Material compatibility | Moderate | Broad, including biodegradable plastics |

| Setup time for new cup type | High | Low due to programmable settings |

| Capital investment | Lower upfront | Higher upfront, but cost-saving long-term |

| Production flexibility | Limited | High |

The comparison demonstrates that high-efficiency versatile machines provide long-term operational advantages, especially for facilities producing multiple cup types.

To fully leverage the capabilities of a plastic cup rim rolling machine with high efficiency, manufacturers should implement the following practices:

Implementing these practices ensures consistent production quality and minimizes downtime.

A plastic cup rim rolling machine with high efficiency is an essential investment for modern cup manufacturers seeking flexibility, speed, and quality. With proper design, adjustable features, and advanced control systems, these machines can effectively handle a wide variety of cup sizes and materials. By understanding the technical capabilities, operational considerations, and industry trends, manufacturers can make informed decisions that enhance production efficiency and product quality.

Investing in a versatile, high-efficiency machine not only reduces operational complexity but also positions manufacturers to respond quickly to market demands, improve cost-effectiveness, and maintain consistent product standards. As the packaging industry continues to evolve, machines capable of adapting to multiple cup sizes and materials will remain critical for competitive production operations.

+86 18621972598

+86 18621972598  +86 186 2197 2598

+86 186 2197 2598  [email protected]

[email protected] No. 565, Xinchuan Road, Xinta Community, Lili Town, Wujiang District, Suzhou City, China

No. 565, Xinchuan Road, Xinta Community, Lili Town, Wujiang District, Suzhou City, China Copyright © 2024 Thermoforming Machine/Plastic Cup Machine All Rights Reserved.Custom Automatic Vacuum Thermoforming Plastic Machine Manufacturers

English

English عربى

عربى 简体中文

简体中文