Main Features

Frame: It is welded with 100*100mm square tube to make the frame more stable. And bolted to key parts as needed for easy installation, disassembly and repair.

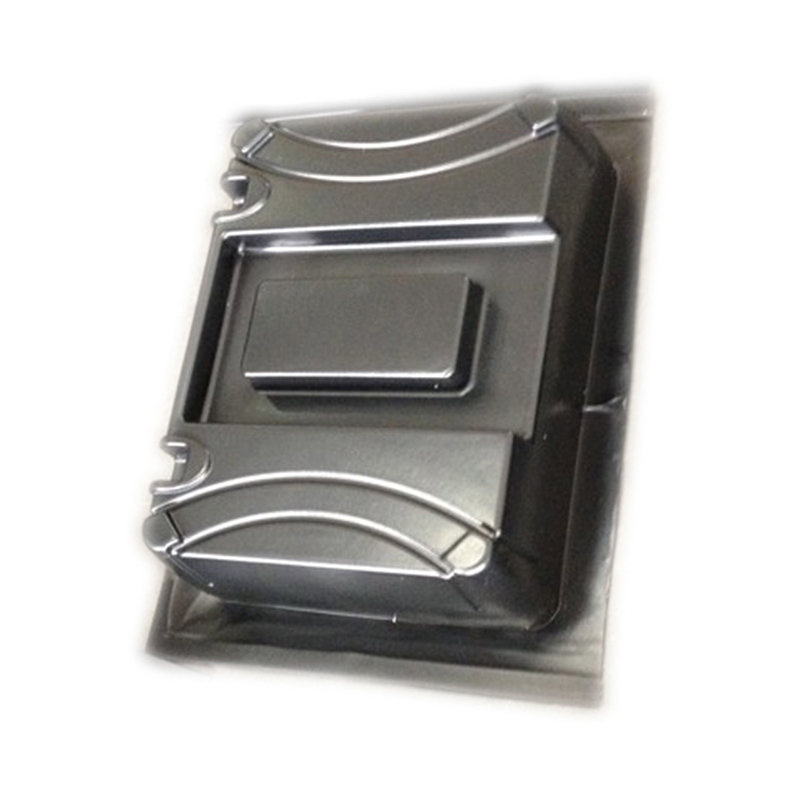

Vacuum Forming Devices:

Moulds Platform: Welded by steel and steel plate. the moulds platform was driven by hydraulic control system. In order to keeping balance the double hydraulic cylinder will move synchronously, thus could prolong the service life. If the dimensions of the moulds changes, new platform should be made accordingly.

Pressing Frame: The pressing frame was driven by pneumatic cylinder and must has enough intensity and stiffness. When the moulds size changes, there is no need to make new frames and just adjust the frame in horizontal or vertical orientation.

Upper moulds (force plug): according to customer's request, and can be assembled with electric adjusting device for precise adjusting.

Cooling System: To be equipped with Cooling Blower. The direction of air outlet could be adjusted, there are 6 Sprayers, could be used for forming control or the cooling of the products.

Protection System: With button position and manual locking, if the Safe door was not closed well or being opened, other operations could not

be operated.

Heating Devices.

Adopt Double side heating, made up of carbon fibre medium wave heating tube, tube carriage and porcelain connector. With the character of instant heating and energy saving, the energy consumption is about 60% of similar machines in the market. f being used intermittently, the

energy consumption even Low.

Heater wire adopted HTW, heating tube connected with SS support by porcelain connector, easy for changing tube.

Temperature control adopt Temperature Control Module, Display and control more accurate, and will not be affected by Voltage fluctuate

Safety Measures:

System have many protection measures, any possible confliction will trigger protection function.

Forming depth.

can reach 2-12mm.

Number of pages corresponding to the album:p17

English

English عربى

عربى 简体中文

简体中文

+86 18621972598

+86 18621972598  +86 186 2197 2598

+86 186 2197 2598

No. 565, Xinchuan Road, Xinta Community, Lili Town, Wujiang District, Suzhou City, China

No. 565, Xinchuan Road, Xinta Community, Lili Town, Wujiang District, Suzhou City, China