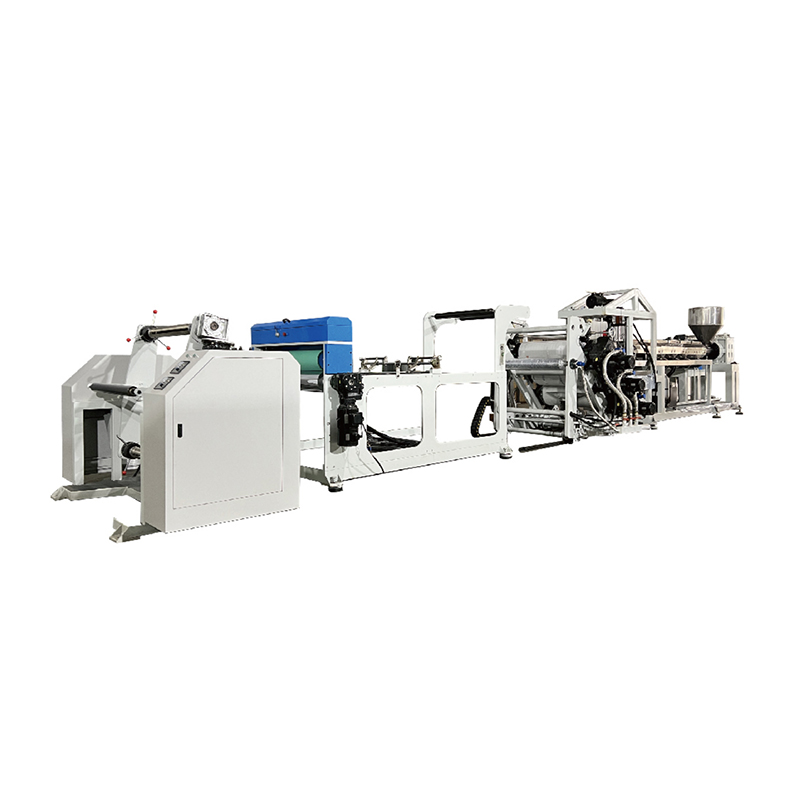

In the modern plastic processing industry, PP/PS/PE/PLA single-screw plastic sheet extrusion thermoforming machines have become the core equipment for manufacturing high-quality and high-precision plastic sheets with their efficient processing capabilities for a variety of plastic materials. The reason why this equipment can achieve this goal is due to the precise design and coordinated operation of key parts such as screws, die heads, temperature control, and screen changing devices in extrusion technology.

As the "heart" of the equipment, the screw starts the first step of plastic processing through a special mixing function. In the face of plastic particles with different physical and chemical properties such as PP, PS, PE, and PLA, the screw uses the shear force and friction generated by the thread structure during the rotation and advancement process, and cooperates with the heating system outside the barrel to promote the gradual melting and plasticization of the plastic particles. Its aspect ratio parameters have been optimized to provide sufficient residence time and mixing space for the plastic in the barrel, ensuring that the material is evenly plasticized and providing a stable and uniform melt foundation for the subsequent molding process.

The plasticized plastic melt enters the hanger-type die head, which is a key component responsible for accurately distributing the melt flow rate and controlling the thickness of the sheet. Based on the special double throttling design, the internal flow channel of the die head can flexibly adjust the melt flow rate and distribution according to production needs. When it is necessary to produce sheets of different thickness specifications, the die head can adjust the throttling structure to make the plastic melt spread evenly at the outlet, effectively avoiding the thickness deviation problem caused by uneven flow of the sheet, and meeting the needs of industries such as food packaging and electronic device packaging that have strict requirements on sheet thickness accuracy.

The temperature control link plays the role of a "stabilizer" in the entire extrusion process. Since the melting temperature ranges of plastics such as PP, PS, PE, and PLA are significantly different and are extremely sensitive to temperature changes, the application of high-precision temperature control systems is particularly important. The system strictly controls the fluctuation range to a very small range by accurately adjusting the temperature of each heating area of the barrel and die head, ensuring that the plastic is always in the best plasticization state. A stable temperature environment can not only effectively prevent the melt from producing defects such as bubbles and weld marks due to overheating or insufficient plasticization, but also regulate the crystallinity and orientation of the sheet at the molecular level to ensure the flatness and mechanical properties of the sheet.

During the production process, filter blockage is a common problem that affects extrusion efficiency and sheet quality, and the application of a hydraulic fast screen changer has successfully overcome this problem. The device uses advanced hydraulic drive technology to complete the filter replacement operation while the equipment is running continuously. When impurities accumulated in the filter affect the permeability of the melt, the hydraulic system responds quickly, pushing the screen changer to quickly switch the filter, and at the same time ensuring that there is no leakage during the screen change process through a sealing structure. This design greatly reduces the equipment downtime for maintenance, maintains the continuity of sheet production, and avoids fluctuations in sheet quality caused by frequent starts and stops.

From the screw's plasticizing of plastic particles, to the die's precise distribution of the melt, to the full-process guarantee of the temperature control system, and the maintenance of production continuity by the screen changer, the key parts of the PP/PS/PE/PLA single-screw plastic sheet extrusion thermoforming machine are closely linked and work together. Together, they build a set of precise and efficient extrusion systems that not only achieve rapid and stable processing of a variety of plastic materials, but also improve the thickness accuracy, surface quality and physical properties of plastic sheets to the industry-leading level through precise control of each link, continuously provide high-quality and reliable basic materials for downstream industries, and promote the plastic processing industry to move towards intelligence and efficiency.

+86 18621972598

+86 18621972598  +86 186 2197 2598

+86 186 2197 2598  [email protected]

[email protected] No. 565, Xinchuan Road, Xinta Community, Lili Town, Wujiang District, Suzhou City, China

No. 565, Xinchuan Road, Xinta Community, Lili Town, Wujiang District, Suzhou City, China Copyright © 2024 Thermoforming Machine/Plastic Cup Machine All Rights Reserved.Custom Automatic Vacuum Thermoforming Plastic Machine Manufacturers

English

English عربى

عربى 简体中文

简体中文