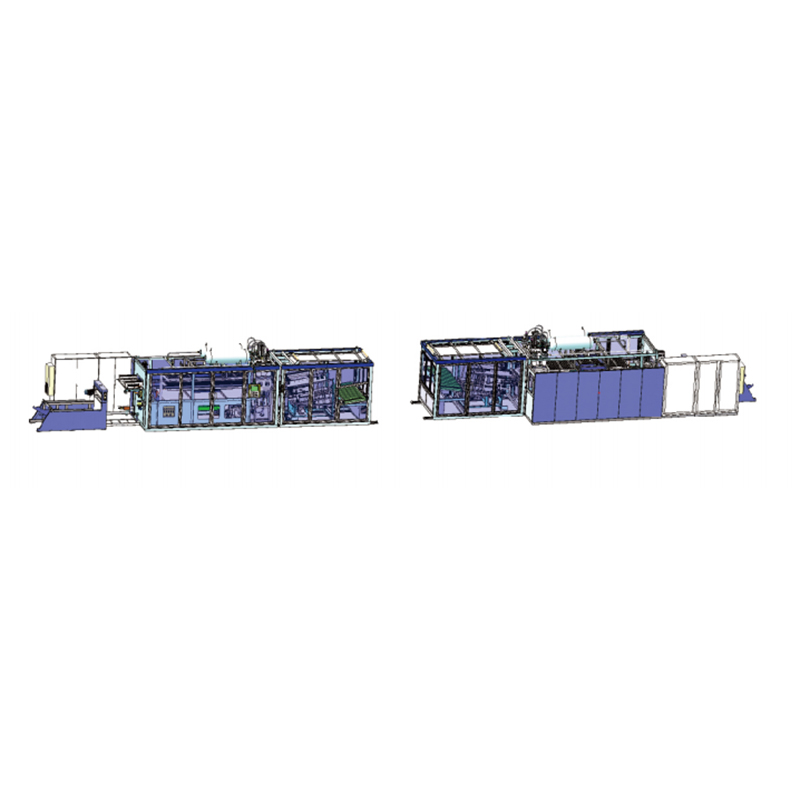

Technical positioning of full automatic tilting mould cup making machine

In the modern industrial production system, the technical iteration of cup making equipment has always been centered around the market's core needs for product diversity, production efficiency and quality stability. As a key equipment in the high-tech industrial field, the full automatic tilting mould cup making machine redefines the scale production standards of cup-shaped products with its unique technical architecture. This equipment is not a simple upgraded version of the traditional cup making machinery, but an integrated solution that integrates material science, precision manufacturing and intelligent control technology. Its original design intention is directly aimed at the current market demand for mass production of multi-material cup bodies such as PP, PS, PET, PLA, etc., especially in the technical adaptability of sauce cups, takeaway hot and cold drink cups, coffee cups and other segments.

Core technical advantages of full automatic tilting mould cup making machine

The realization of the efficient production capacity of the full automatic tilting mould cup making machine is due to the synergy of the innovative heating system and streamlined production process. Through the precise control of the temperature field during the material shaping process, the molding cycle of a single product is shortened to avoid material performance loss caused by uneven heating. The multi-material compatibility is based on the in-depth analysis of the physical properties of different polymer materials. Through the adjustable process parameter module, the equipment can automatically match the best molding conditions according to the differences in material melting point, ductility, etc., and can quickly switch from hard PS cups to environmentally friendly PLA cups without frequently replacing core components. High-precision molding is another highlight of the equipment, with closed-loop linkage between its precision molds and intelligent control systems. The mold is made of aerospace-grade alloy materials and processed with ultra-precision to ensure that the cavity size error is controlled at the micron level; and the industrial-grade PLC control system can correct the pressure fluctuations during the molding process in real time, so that the wall thickness uniformity and mouth flatness of each batch of products remain highly consistent. This stability is not only reflected in single batch production, but also maintained for a long time through the sturdy fuselage structure and redundant design of key components. The main body of the equipment adopts an integral casting process, and the transmission system uses high-wear-resistant bearings. With the regular maintenance and early warning mechanism, the reliability of continuous production is guaranteed from the mechanical structure level. Convenience of operation and maintenance is also an important part of its technical advantages. The touch-screen operation interface of the equipment converts complex process parameters into intuitive graphical instructions. Operators can complete production parameter setting and status monitoring after simple training; and the modular component design allows daily maintenance without professional tools.

Cup making machine's scene adaptation capability

The expansion of the application scenarios of the full automatic tilting mould cup making machine is essentially the result of the precise docking of its technical characteristics with industry needs. In the field of food packaging, in response to the strict requirements of sauce cups on sealing performance, the equipment eliminates the stress concentration point at the bottom of the cup body through the inclined mold tilting molding technology to ensure the leak-proof performance when holding liquid sauces; in the beverage packaging scenario, its optimized processing ability for PET materials enables the cup body to have sufficient compressive strength and transparency, perfectly adapting to the filling and transportation needs of hot and cold drinks; in the field of daily necessities packaging, the smooth processing of PLA materials responds to the current trend of environmentally friendly packaging, providing stable production capacity for the large-scale production of degradable cup bodies. This cross-domain adaptability is a reflection of the scenario-based thinking that was embedded in the equipment during the design phase. By analyzing the differentiated requirements of different industries for the physical properties of the cup body, common requirements are transformed into basic functional modules, and individual requirements are flexibly adjusted through optional configurations, forming a comprehensive solution that can meet food contact material safety standards and adapt to different circulation environments.

+86 18621972598

+86 18621972598  +86 186 2197 2598

+86 186 2197 2598  [email protected]

[email protected] No. 565, Xinchuan Road, Xinta Community, Lili Town, Wujiang District, Suzhou City, China

No. 565, Xinchuan Road, Xinta Community, Lili Town, Wujiang District, Suzhou City, China Copyright © 2024 Thermoforming Machine/Plastic Cup Machine All Rights Reserved.Custom Automatic Vacuum Thermoforming Plastic Machine Manufacturers

English

English عربى

عربى 简体中文

简体中文