PET film laminated thermoforming refers to a process in which PET sheets are laminated with functional or decorative films and then shaped using thermoforming technology such as vacuum forming or pressure forming.

This process combines PET’s clarity and strength with the enhanced appearance and functionality provided by laminated films.

Premium visual appearance (metallic, glossy, matte, holographic)

Excellent food safety performance

High structural strength and rigidity

Improved barrier properties

Good recyclability and sustainability

Widely used for:

Bakery trays

Ready-to-eat food containers

Sushi and fresh food trays

Chocolate and confectionery inserts

High-end takeaway boxes

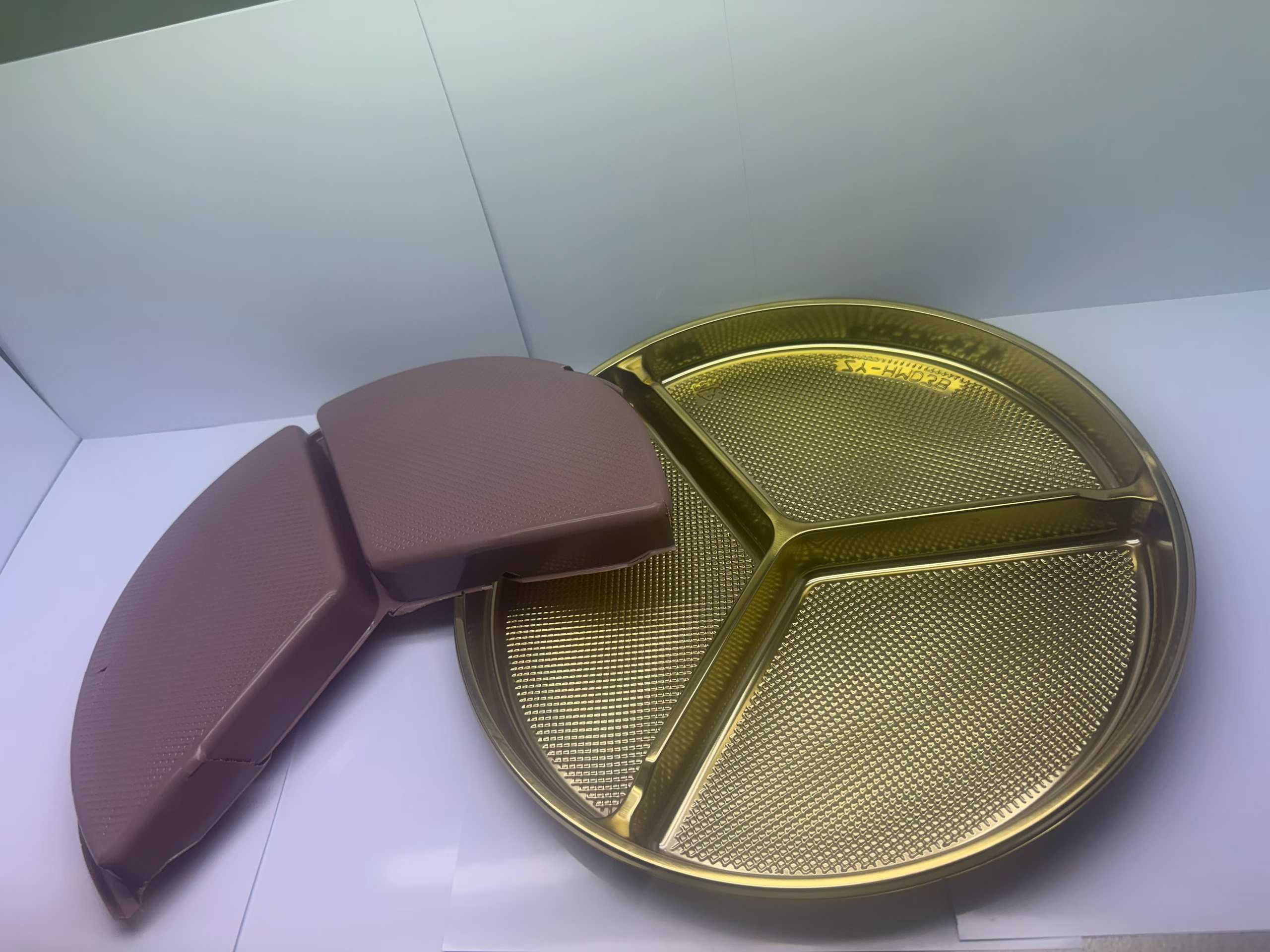

Compartment meal trays

Customized branded packaging

Cosmetic inserts

Electronics inner trays

Festival gift packaging

Industrial component trays

Medical and electronic packaging

Premium and branded packaging growth

Customized and small-batch production

Eco-friendly laminated materials

Automation-friendly packaging designs

Q1: What’s the difference between laminated and normal PET thermoforming?

Laminated PET offers better appearance and functionality than standard PET.

Q2: Is it food-safe?

Yes, when food-grade PET and films are used.

Q3: Can it be customized?

Absolutely. Size, shape, film type, and structure can all be customized.

Q4: Is it environmentally friendly?

PET is recyclable, making it a sustainable packaging option when properly designed.

+86 18621972598

+86 18621972598  +86 186 2197 2598

+86 186 2197 2598  [email protected]

[email protected] No. 565, Xinchuan Road, Xinta Community, Lili Town, Wujiang District, Suzhou City, China

No. 565, Xinchuan Road, Xinta Community, Lili Town, Wujiang District, Suzhou City, China Copyright © 2024 Thermoforming Machine/Plastic Cup Machine All Rights Reserved.Custom Automatic Vacuum Thermoforming Plastic Machine Manufacturers

English

English عربى

عربى 简体中文

简体中文