Technological Innovation

As China Automatic Vacuum Thermoforming Machine Manufacturers, Innovation is the...

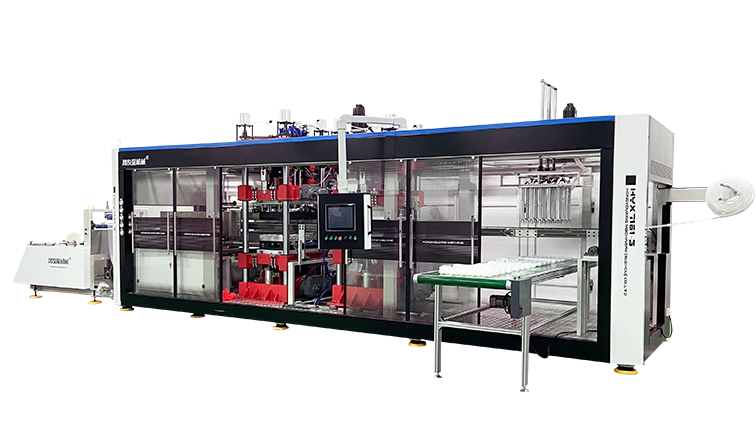

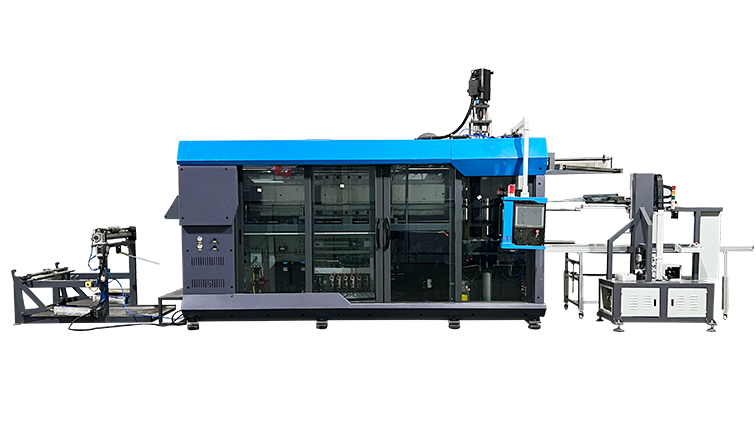

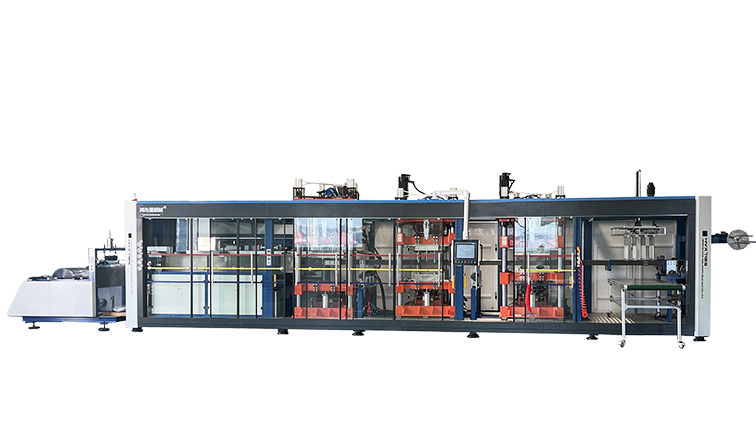

View more >>Yiyou Electromechanical independent R & D and production of positive and negative pressure integrated machines, punching, cutting and stacking machines with independent intellectual property rights.

Industry Experience

Cover Area

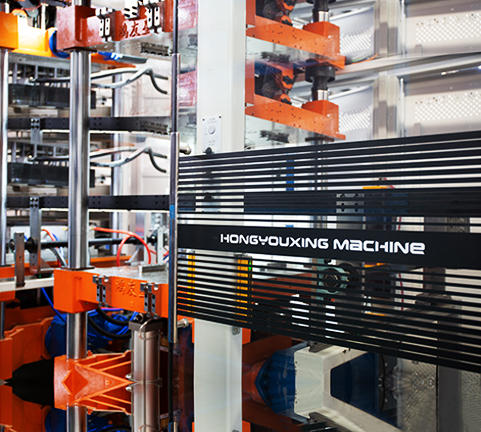

Advanced Equipment

Global Business

As China Automatic Vacuum Thermoforming Machine Manufacturers, Innovation is the...

View more >>

We produce over 500 models of various types, and can develop and produce with di...

View more >>

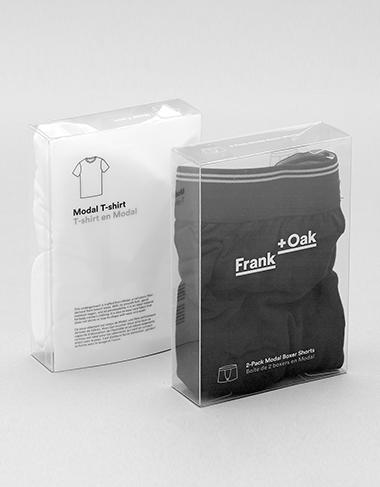

Hongyouxing Machinery provides one-stop service for molds and materials, to reli...

View more >>

We wholeheartedly train and recommend operators for customers, and provide one-s...

View more >>

As China Plastic Cup Machine Factory, Our Goal is to contribute to global sustainable development and resource recycling, and to develop and implement sustainable technology complete solutions to provide to our customers.

The way a hydraulic cutting machine is moved has an important impact on its port...

In the tire vulcanization process, the role of rim rollers is crucial. Vulcaniza...

In the field of medical device manufacturing, thermoforming processes are widely...

How does Thermoforming Machine ensure efficient and stable continuous operation ...

In today's industrial manufacturing field, thermoforming auxiliary equipment is ...